Earlier in March, Softbank started offering a hybrid private network offering that it termed as “shared-type” Private 5G. The article said:

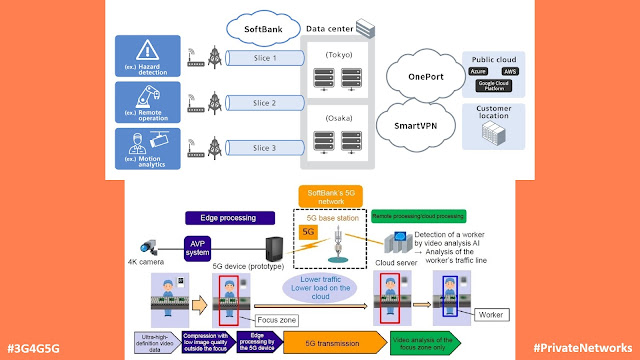

Private 5G (shared type) realizes high-performance and secure wireless communications by utilizing a technology known as “network slicing,” a technique enabled by 5G standalone (5G SA) technology that divides a single network into multiple virtual connections that use dedicated computing resources. This makes it possible to “slice” or apportion sections of a network for specific customer uses.

As a result, enterprise customers can quickly equip facilities like large factories with wireless connectivity without spending time on network construction and operation. Network slicing reduces network congestion, which is useful for applications that require stable connections, such as hazard detection or the remote operation of equipment.

With the provision of its Private 5G (shared-type) service, SoftBank will work to enhance what’s called the Operational Technology (OT) domain–which covers the control of equipment in factories and buildings–and integrate IT systems with OT systems, which have been largely fragmented until now.

Later in the fiscal 2023–the year ending on March 31, 2024–SoftBank plans to provide a “Private 5G (dedicated)” service, which will offer an advanced private 5G network environment through the installation of dedicated base stations and equipment on a customer’s premises.

Then in June, a press release said:

SoftBank and Sumitomo Electric have conducted demonstrations jointly to realize 5G-based smart factories since 2019. In a trial conducted from December 14, 2021 to July 6, 2022, the movements of factory workers were captured using a 4K camera installed at Sumitomo Electric’s Osaka Works. The ultra-high-definition video was compressed by AI-based video processing (AVP) –Sumitomo Electric’s proprietary video compression technology–and was transmitted to a cloud server via SoftBank’s 5G network to conduct AI-based video analysis.

The use of AVP reduced data volumes by 88% compared to conventional compression methods. Furthermore, the video-based worker detection rate improved from 89% to 100%. While workers with small image sizes could not be detected in previous trials, the use of video captured by an ultra-high-definition 4K camera improved the accuracy of AI-based video analysis, bringing the detection rate up to 100%.

The technology used in the demonstration made it possible to quickly identify tasks that took more time than planned, implement countermeasures, and improve productivity. The demonstration results are also expected to improve safety by monitoring workers and their pathways.

We have yet to see live demos from Softbank but hopefully soon.

Comments

Post a Comment