Ports are undergoing a profound transformation as they evolve into intelligent logistics hubs. The enabler behind this shift is the private 5G network. With its combination of low latency, high reliability and broad coverage, private 5G is emerging as the connectivity foundation that smart ports need for real-time operations, automation and data-driven decision making.

Among the organisations leading this change, China Mobile International (CMI) has demonstrated a comprehensive approach to port digitalisation. I first heard about its "5G Smart Solutions" at PortComms 2024, in a presentation by Allan Zheng, Senior Director Europe Region at CMI. Earlier this year, the company shared a more detailed overview through the GSMA, outlining how its end-to-end 5G Smart Port Solution is already enabling large-scale automation and efficiency gains at several major ports across China.

Private 5G networks are well suited to port environments. Unlike traditional fibre-based systems, which can be costly to deploy and inflexible to maintain, 5G enables rapid coverage of large areas and dynamic reconfiguration as port layouts or operational needs change. The wireless nature of the network also removes constraints related to cable routing, making it ideal for both new builds and retrofit scenarios.

One key application is the remote control of port cranes. These massive machines, essential to container handling, are typically operated manually under challenging conditions. By using private 5G to support remote operation, ports can centralise crane control in safer environments while boosting productivity. CMI reports that a single operator can now manage multiple cranes, delivering more than 30 percent efficiency gains and significantly reducing labour costs.

Private 5G also supports autonomous vehicles for horizontal container transport within the port. These vehicles are equipped with high-precision positioning and onboard sensors, coordinated by intelligent scheduling systems that take advantage of the network’s low latency and reliability. This enables continuous 24-hour operations, reduces reliance on human drivers and contributes to carbon savings, especially when combined with electric vehicles.

Another area of impact is container tallying. Traditionally a manual task, it can now be automated using high-definition cameras, AI-based image recognition and edge computing. This results in quicker, more accurate validation of container numbers and conditions, reducing both human error and operational overheads.

Beyond automation, private 5G also supports a wider set of smart services, including video surveillance, autonomous inspections using drones or ground robots, and intelligent lighting and energy management. These are integrated through a centralised operations platform that aggregates data from across the port to support decision making, predictive maintenance and rapid response to incidents.

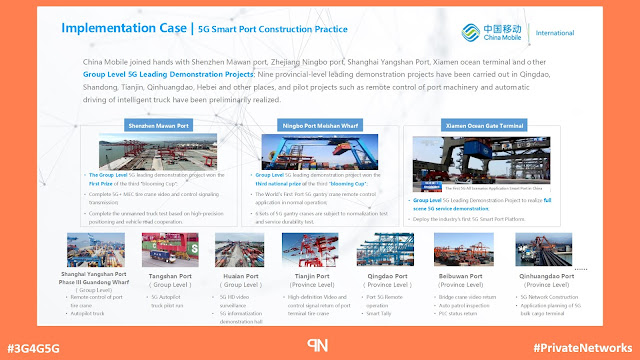

According to CMI, ports such as Ningbo Meishan, Shenzhen Mawan and Xiamen Ocean Gate have already implemented these solutions with measurable success. These include remote operation of gantry and rail cranes, driverless container trucks, AI-enabled tallying and video analytics-based safety systems. These are not pilots or proofs of concept, but fully operational deployments demonstrating the reliability and scalability of private 5G in port environments.

As ports adapt to growing volumes, increasing automation and more ambitious sustainability goals, private 5G is becoming critical infrastructure. It provides a single, robust network that can support a wide range of operational needs, from crane control to digital twin platforms. CMI's work, as presented via GSMA, offers a compelling example of how private 5G can underpin the smart ports of tomorrow.

Related Posts:

- Private Networks Technology Blog: The Use of Mobile Private Networks (MPNs) in Ports

- Private Networks Technology Blog: GSMA APAC Joint Forum Explores 5G's Impact on Industry Transformation in APAC and Europe

Comments

Post a Comment