Alcatel Submarine Networks (ASN) is a part of Nokia and leads the industry in terms of transmission capacity and installed base with more than 700,000 km of optical submarine systems deployed worldwide, enough to circumnavigate the globe 17 times.

Back in Dec. 2022, ASN inaugurated the deployment of a private 5G network on its submarine systems production and assembly site based in Calais. Quoting from the press release:

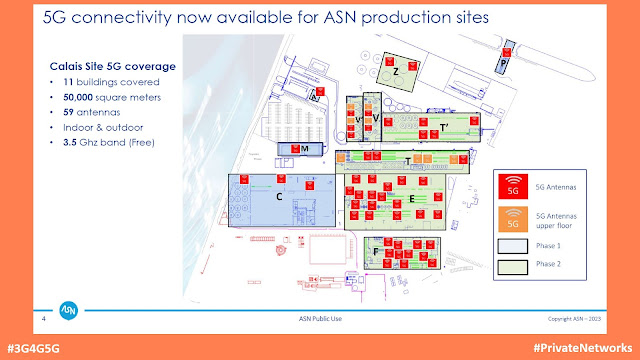

More than 2 years of development and integration were necessary to deploy the largest private industrial 5G network in Europe to date, and to provide coverage to the 50,000 sqm of the Calais site; eventually, 11 buildings as well as the loading docks will be covered by 59 5G small cell antennas (57 indoor emission points and 2 outdoor emission points).

The deployment of this 5G network and the Industry 4.0 program is the result of collaboration between ASN and its strategic partners Nokia, Iliad, Free Pro, Sopra Steria and BSCA.

This network, supplied by Nokia, will be one of the key elements of ASN’s Industrie 4.0 project, an ambitious digitalization plan that aims to modernize ASN’s industrial processes, optimize operational performance and improve working conditions for employees. This private 5G network will also enable the implementation of industrial IoT with many use cases already identified to monitor and improve the performance of the production site in Calais.

Based on a secure, high-speed and reliable network, the use of 5G will improve industrial processes based on the automatic collection and processing of factory data and accelerate the integration of the Internet of Things (IoT) in industrial production. Predictive algorithms will facilitate the anticipation of production and the efficient management of the storage of manufactured cables, a critical issue for the factory.

Among the use cases already developed, several were presented at the inauguration:

- Digitization of industrial processes, dematerialization of all procedures allows greater accessibility and ensures that operators have permanent access to reliable and up-to-date documentation

- The filling management of the cable storage tanks thanks to laser sensors, allowing the tanks’ availability monitoring

- Optimization of energy resource management through the implementation of an energy consumption monitoring system in the factory’s buildings

- Assistance in the maintenance of equipment in workshops by using connected glasses to provide remote maintenance support

- Analysis of production incidents that can be connected to different production equipment in order to anticipate and determine breakdowns

The deployment of the 5G network is a concrete step in ASN’s Industry 4.0 strategy, which aims to combine virtual and real environments in order to interconnect the company’s departments and activities around industrial operations: purchasing and procurement, logistics, production, maintenance and supervision, etc.

This approach affirms the key role of ASN’s industrial tool in its leadership position in the subsea systems market.

The pictures above are from the slides presented by Christophe Bejina, CIO at ASN at the Future Enterprise Networks (FEN) Conference in London in June 2023.

You can download the case study on this from here.

Related Posts:

- 3G4G: Industry 4.0, IIoT, IoT & 5G

- Connectivity Technology Blog: 5G IoT for Industry 4.0

- Private Networks Technology Blog: Private 5G for Industry 4.0

- Private Networks Technology Blog: AWS Edge to Power Private Networks and Industry 4.0

- Private Networks Technology Blog: Case Study on Industrial 5G Service of Sejong Telecom in Korea

- Private Networks Technology Blog: Siemens Enables the transmission of Profinet IO via a P5G network

- Connectivity Technology Blog: Samsung to showcase benefits of 5G in Industry 4.0 with IBM, IMDA & M1 in Singapore

Comments

Post a Comment